We are here to master of a few worthy things...

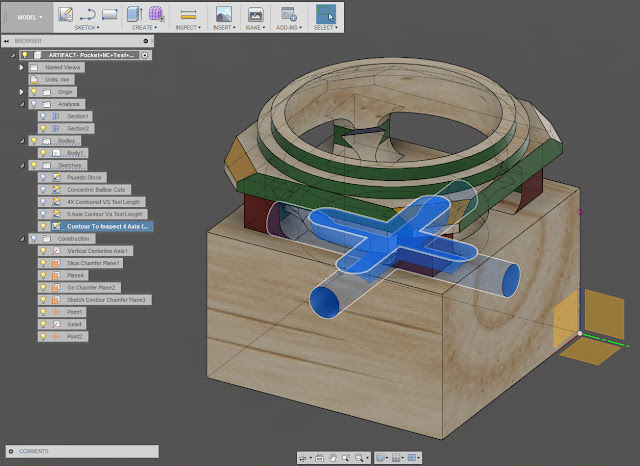

The intent of this site is to offer insight: To

blend select art forms with the use of

with the latest technologies all

to make extraordinary things. While there will be a heavy interest in quality jewelry making it's not limited to just that.

Typically

with various art forms there are subject matter experts. They stick to their area of expertise. This is a place where that

tradition will be broken!

The goal here is

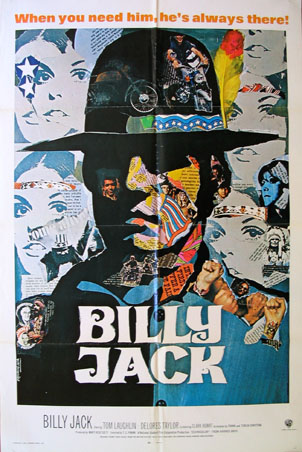

not to be some "

Jack of All Trades, Master of none". It's about finding the right overlap of art and technology, to make some remarkable things that have not been made before, that needs to be made!

For those that follow along, we say let the

universe inspire us like never before!